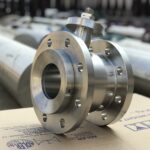

Basic features for end tank execution ball valve with tilted 15° stem type “FA8”

Tilted stem essential to avoid interference with the tank bottom

Oversize upper flange

Protrude ball to avoid product settling in the bottom of the tank

Coupling between valve – bottom tank, by adopting male / female connection to minimize empty spaces

Metallic cavity filler seats in order to minimize product between valve body and ball

No elastomer seals. Adler valves are supplied only with inertial polymers (PTFE)

Valves certified L.R. : ATEX and FIRE SAFE

Valves certified TUV : ISO 15848 class “A” fugitive emissions

Valves and pneumatic actuators certified S.I.L. 3

Note: wafer type ball valves adapted as end tank execution is a poor and makeshift solution, because, obviously, they do not have features as above detailled